27WON CAI, DOWN-PIPE, FP

There are two easy ways to get more performance out of a turbocharged car.

Make it easier for air to get in and make it easier for air to get out. On this new 10th generation Honda Civic the best place to start is with a performance cold air intake and downpipe. Both of these items are readily available, easy to install, and give some great bang for the buck.

We designed our CAI to be a straight and easy INSTALL with no tuning required.

All the hardware and parts needed are included in the kit and this is the only cold air system on the market that will work on the Canadian model cars with no alterations. In the Canadian model Civics, the windshield washer reservoir is located in the lower left front fender. This space is where the filter element for a typical cold air intake system is placed. Because of this, you cannot run a CAI on a Canadian Civic unless you relocate the bottle to the other side of the car. We designed this kit with this in mind.

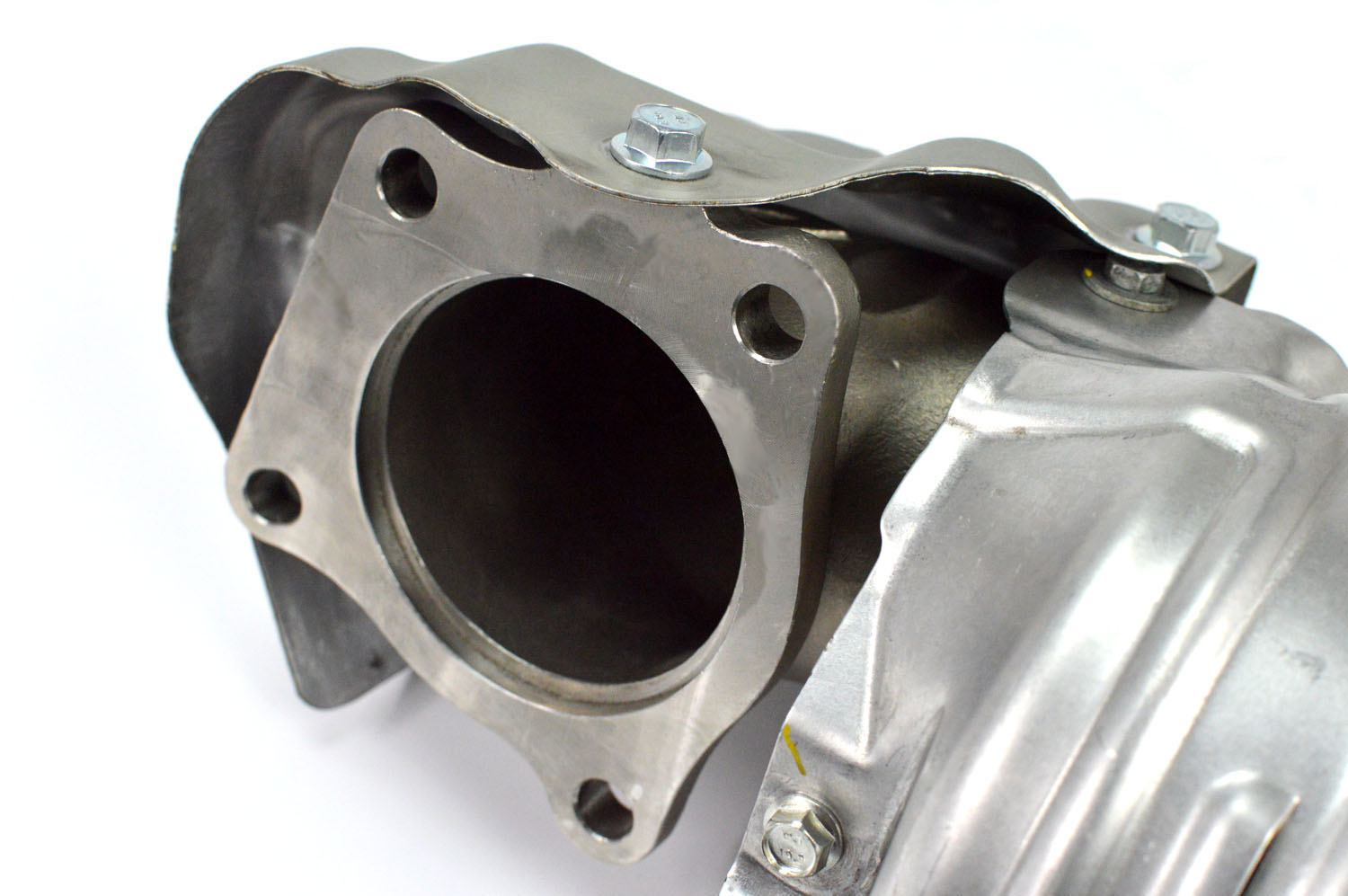

Our downpipe uses an 80mm bellmouth opening which is the largest on the market.

Now, why is this important?

Turbochargers function a lot on pressure differences and the greater those deltas the easier the car can breathe.

It works like this.

As the car goes through the combustion process there is a huge increase in cylinder pressure. This is the force that acts on our piston and creates the work that it needs to make our engine move and make power. When the piston is on its way back up and the exhaust valves are open all the spent gas that is still under pressure is exiting the ports and going into our turbocharger to spin the turbine wheel. Once it is done doing work on the whee,l the spent gases now need to exit the turbo through the exhaust system as quickly and efficiently as possible.

So how can we aid in that evacuation of the spent gasses? The answer is by making the area behind the turbine wheel as low a pressure zone as possible. This encourages the spent gases to move out quicker. We achieve this by using the large 3.125” exit and making the pressure delta as great as we can. This is a case of bigger is better.

PART BREAKDOWN

Manufacture: 27WON Performance

Part #: L15-6-209-10, L15-6-209-12, and L15-6-305-15210

Components: Hybrid Cold Air Intake, Cast Stainless Steel Downpipe, Stainless Steel Front Pipe, All the clamps, brackets, and hardware needed for installation

Specs:

Billet Machined MAF

Clear Lexan Cover

100% OEM Fitment (no cutting or modding required)

All OEM Heat Shields Retained

Full T304 Stainless Steel Components and Hardware (will not rust)

We completed our intake and downpipe install with the addition of our front-pipe. By going to a larger size front pipe we achieved the same effect as the down-pipe, this helped further reduce back pressure in our exhaust system to allow for a more free-flowing set-up.

While the OEM exhaust does a great job of supporting the stock turbocharger at stock boost our new larger pipes will help make sure things continue to breath easy as the power mods start to stack up, especially when we drop in our W1 turbo upgrade.

27WON PRO TIP:

The OEM turbocharger studs are notorious for breaking off in the turbine housing when installing an aftermarket down-pipe upgrade. When planning swap downpipes we suggest applying penetrating oil at least 3 hours in advance. Let this soak in. It’ll make removal easier.